History an

KIARANI

History and Details

Mr Reg Hyde, Master Boat Builder, Stockton, Newcastle, NSW. Reg commenced boat building in 1960 specialising in fishing vessels under a 100ft.

Kiarani was built in 1977 at the Stockton Shipyards near Fern Bay, she was a 11.3mtr Sharpie Fishing Trawler with a tugboat wheelhouse and 7mtrs of open deck designed for commercial fishing. Similar to the photo Reg is holding, sadly there are no early photos of Kiarani available.

Kiarani was retired from commercial fishing around 1997-8. Her new owner (name unknown) re-fitted her as a day fishing boat for tourists, extending the roofline all the way to the transom and building in the cabin area to include a rudimentary kitchen and toilet. For the next 10-12 yrs until around 2010 Kiarani plied her trade as a day fisher between Nelson Bay, Forster and along the coast as far as Port Macquarie.

It’s about here that Kiarani‘s story gets a little fuzzy and we have a missing 4-5 years, next we hear of Kiarani she is found in disrepair in a boat yard on the Sunshine Coast at Mooloolaba where a father and son - Mr Murray Phipps (Pictured) buy her for the yard fees that were owed.

The father and son then started a full re-build, starting with the hull and working their way up, pulling the motor and gearbox and sending them away to have them reconditioned, installing new fuel tanks, re-wiring and replacing steering, dash, aerial’s etc, Kiarani was taking shape but was still a little rough around the edges aesthetically.

Murray (who works in the gold and diamond mining industry) contacted local Brisbane shipwright and wooden boat specialist Peter Kerr at the Deagon Slipway, to do the next stage of the refit and moved Kiarani from the Sunshine Coast to Deagon to have the hull, decks and cabin added to and worked on giving a more professional finish to the boat.

Murray - God love him - spent approximately $80,000 on the first round of the rebuild, including the drive chain rebuild.

One of the features, that Kiarani is known for, is her striking 16mm thick angled and tinted heavy duty glass front window.

It looms over the foredeck making the big sturdy anchor winch (pictured below) take a back seat (we love the winch so much) and has been fitted so no re-enforcements or supports are visible, the bevelled glass being held in place by two hidden metal tracks above and below the variously angled glass panels.

Mr Reg Hyde

Mr Murray Phipps

Kiarani Foredeck and winch

Its here that we come into the picture, we discovered the boat for sale and contacted Murray who told us that he has to sell the boat because his wife refuses to come aboard after the last trip (Mooloolaba to Morton Bay, Deagon) apparently the weather had been a little lumpy with a healthy following wind and sea and Mrs Phipps absolutely did not like the way the little trawler delt with it (Note: we have surfed this trawler down 2mtr waves in crap weather with zero issues this little boat loves a following sea) Mrs Phipps had been used to Murrays previous boat a 35ft Bertram, with considerably more power and totally different ride and had decided that Kiarani was not her style at all. We felt sorry for Murray as he had always dreamed of owning his own little wooden trawler and was devastated that his wife had shut the door on that dream asking him to sell the boat post haste.

Kiarani when we first bought her

Heavy Duty and Unique Windscreen

Another feature Kiarani is known for is a stylish chrome faux exhaust stack and chrome breather pipes, in actual fact the boats exhaust system is a wet system venting below the duckboard at the rear of the boat.

Faux Exhaust Stack

Faux Breather Pipe

Andrew & Rachel in the Whitsundays

Chloe, tank racks and dive platform

Chloe's beautiful lines and huge back deck

Andrew very happy with the Rosewood Wheelhouse refurbishment

About Us

Hi, we're Andrew & Rachel, we have had the pleasure of owning Kiarani since 2018.

Andrew has always had a thing for wooden boats, if you ask him, he’ll tell you it’s a childhood thing, he loves the smell of the boats especially when they’re working hard in a decent sea and you can smell the wood rubbing together, the creaking and groaning, the way they move at sea and a myriad of things about them, prior to owning Kiarani, Andrew owned a 55ft Sharpie Trawler named Chloe which he purchased in Wollongong, NSW and then drove back to Qld.

After suffering a setback getting through the Ballina bar in bad weather and being forced to lay up for repairs Andrew continued on to his final destination in the area of Breakfast Creek, Brisbane where he began the task of totally refurbishing the boat, staying as true to the original as he could.

Andrew is also a Master SCUBA Diving Instructor and had planned to use Chloe as a dive boat on completion. Sadly, in one of Brisbane’s huge Xmas storms (2016) while parked in the Bulimba creek near the 60-ton lift yards at Murarrie awaiting a new motor she was struck and holed by a large steel trawler which had broken its mooring and bounced of several boats before striking and sinking Chloe. In a moment 5 years of hard work became a fish house at the bottom of the creek, Andrew went and got very drunk.

It took a couple of years for Andrew to get over losing Chloe and to be prepared to take on another wooden boat project but in company with his new wife did just that with Kiarani.

When we first purchased Kiarani

After purchasing Kiarani from Murray and spending a few weeks getting to know her the first thing we decided to do was fit a duckboard and storm covers, another uniquely Kiarani feature is the see through transom hatch, and whilst a great feature, getting back on board after a swim was a pain in the ass! So back to Peter Kerr at the Deagon Slipways she went, our instructions to Peter was to build a nice strong duckboard and did Peter ever deliver hahaha, it does raise up but only with great effort (a little over engineered) and so has spent most of its time in position at the rear ready for a swim

Having done the basics, we took the boat north to the Whitsundays and to her final destination at Airlie Beach, enjoying a brilliant 5–6-week journey along the coast and seeing all manner of fantastic ocean life from whales and dolphins to masses of turtles at one of the moorings. Next we will give you all the technical details starting with the survey report we got on purchase.

Transom Hatch

Duck Board

After getting the rear access sorted, we had storm covers made and fitted to make the lovely rear deck (approx. 4sq mtrs) more user friendly. At a later date inserts were added to the storm covers to allow better air flow while at anchor.

Technical Stuff

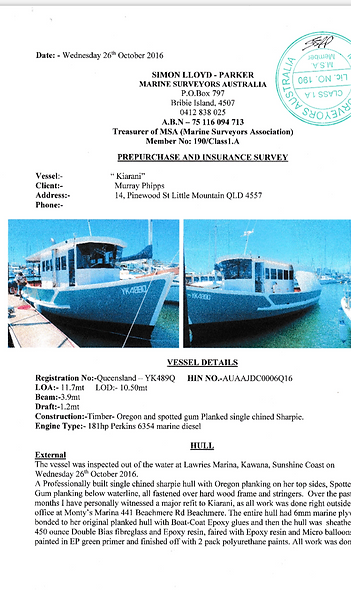

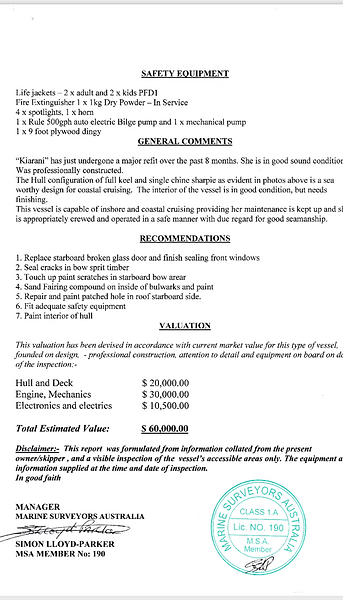

Kiarani’s survey report on purchase to Murray Phipps. This gives you all the technical information you require for the boat, its LOA, weight, height, width, what motor is powering it and the horse power – NOTE: cruising at approx. 7/8 knots the motor uses approx. 8 litres an hour – we calculate fuel capacity and overall milage on 300ltrs = about 300 nautical miles or 540klm with reserves of about 80ltrs or another 140klm. The boat will do up to 10-11 knots on a fast current with a tail wind and the skipper yelling out the wheelhouse door and making whipping motions, well at least we managed this coming out of the Narrows north of Gladstone 😊but usually we cruise at 7-8 knots, this boat loves a following sea and is in her element bashing nose first into it as are all sharpies. NOTE! THIS BOAT WILL NEVER NEVER NEVER GET UP ON THE PLANE IT’S A TRAWLER FOR GODS SAKE! I can’t believe I even have to say this, but apparently, I do.

Our Renovations

After arriving in Airlie Beach – our home port – we didn’t do much to the boat, instead we used her – a lot – after about 12 months we had a better idea of what we wanted to do and set about doing it, first thing was the galley, it sucked! and was ugly as fuck and my wife insisted we do something, so we had a local cabinet maker make up a kitchen for us we added some specialty wood pieces from a local guy, raised the skippers chair and added a foot box and revamped the head and added a shower – see photos before and after.

Before – no stove or shelves or lockable cupboards

During the rip out phase, we noticed that a lot of the cedar was very water stained, this triggered a repaint

Rachel hard at work, she literally put her blood sweat and tears into this boat.

Coming along nicely, just getting to the finishing details😉... Or so we thought, then we looked in the pointy end, shudders, yuck isn’t a strong enough word so we had to have a go down there as well

During the internal renovation process, I poked things I shouldn’t have, this resulted in a wheelhouse rebuild as well.

Roxy the boat dog inspecting the work, she came back and said she thought the deck needed a tidy up now…..sigh….ok lets do it

First Sanding and repointing the screw holes

But look pretty dam good after several coats of varnish and a decent sanding

While we were there, we added an outside cupboard with a hardwood top seen on the left, very handy for morning coffee service and outdoor storage! Then came the steering wheel saga, seriously nothing prepared us for this, we couldn’t for the life of us find a new steering wheel that fitted, let alone looked good, so we thought “why not refurbish the old one”, my very diligent, patient and soon to be driven crazy wife took the task on, the photo below shows how it looked when she started, a horrible motley grey and white with what appeared to be several coats of paint – see photo below

This was with the first 2 of 8 coats of paint removed. The best part was that each layer was a different type of paint - Oil, Enamel, Lead Based, and goodness knows what. So you'd work out how to remove a layer, and then have to test all known paint removal options again for the next layer 🤣

For over 30 hrs, yep 30 hours, Rachel sanded, scraped, heat gunned, paint stripped and picked meticulously with sharp objects in order to bring the wheel back to its former glory. Kept company and assisted by Roxy of course.

A Thing of Beauty

And Patience

To complete the internal fit out, we also trimmed windows, added curtains, a fold down dining table, cupboards above the galley and fridge and also in the shower and head, curtains for privacy in the shower area and a wet floor and drain. And then of course we sat down and had a meal to celebrate (just prior to falling in a heap).

As we all know there's no rest for the wicked and it was time to tackle below the water line, a crappy job at the best of times.

The rudder and propeller cleaned and coated in Prop Speed. Looking very nice and hopefully will glide through the water. Fully re anti-fowled and new anodes.

Our Renovations: Part 2

Then we rested, played, fished and dived and enjoyed the beautiful Whitsunday Islands. Fast forward to 2022 and both Rachel and I had spent two years recovering from various accidents that left us with broken legs, ankles and ribs, several plates and screws between us and Kiarani was not getting her proper use or maintenance. Xmas of 2023, we pulled her from the water with object of doing all those little things that wooden boats need doing to them, we put her up on the hard in Edges Boat Yard and promised to get to her after Xmas and New Years was over. Then I had yet another accident and tore the femur muscle and damaged the femoral nerve in my right leg, we also decided to sell our home and try and get something a little bigger for our dogs to run around in (we breed English Bulldogs) and eventually settled on a lovely house with a massive shed in Home Hill, an hour south of Townsville and two 1/2 hours north of Airlie.

Yep, that was an issue! a new to us house requiring work and a two 1/2-hour haul to the boat yard. Yes, you guessed it the work on the boat kept getting put off. So very dumb of me and I knew better. When I finally got to the boat, I discovered all manner of issues not the least of which, was a leak in the roof near the exhaust stack which had polluted the roof in a major way causing rot all over the dam place……sigh.. so, we started the next round of repairs.

Yes, we tore the roof off! Well 90% of it anyway, chasing water damage is a bitch.

Thank goodness for our Master Carpenter Peter's skills in repairing this.

Not pretty, slightly terrifying and in honesty more than a few tears were shed

Even the roof on the back deck needed to be repaired and replaced.

It's amazing what a couple of weeks work and several thousands of dollars will do. Figured while we were there, we’d brighten up the paint work and repair some chips and sun crazing. Re-doing the antifouling – again (normally done every 18 months).

Almost back to normal! Just a few more coats of paint to go!

After much scrubbing and sanding. Many hours, not to mention miles of masking tape and litres upon litres of paint, she's looking glossy and gorgeous.

KIARANI

For further information please contact:

Andrew Dalton phone: 0412 585 388

or email: andrewcdalton@hotmail.com